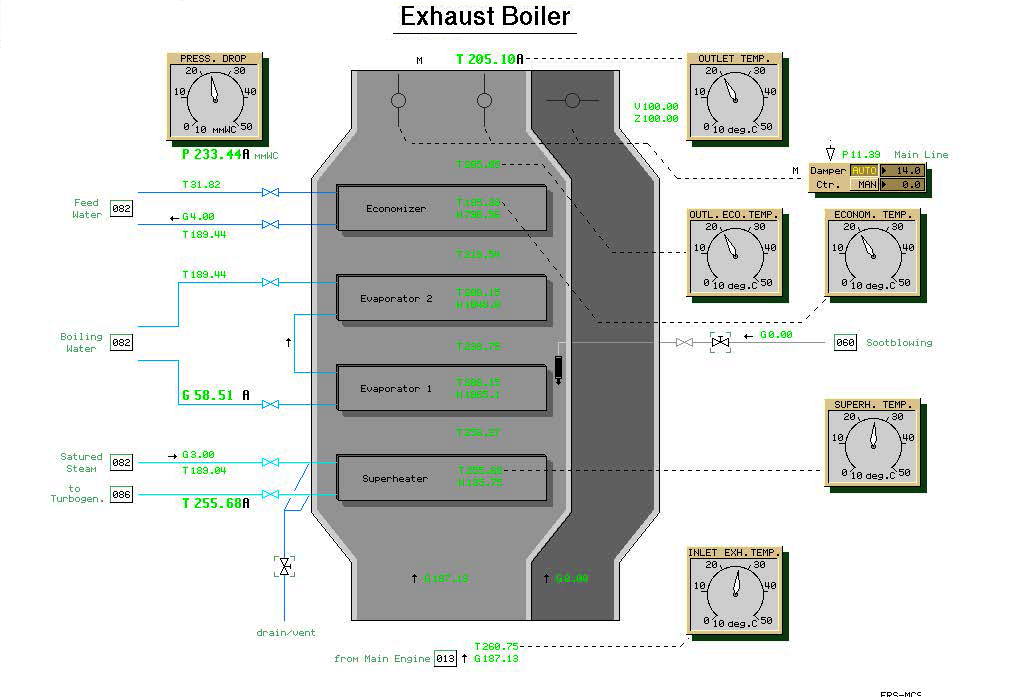

The exhaust from the main engine(s) is cooled in an exhaust boiler before entering the stack. At full power, the steam generated in the exhaust boiler is sufficient to drive the turbo-generator and supply steam for various heating purposes.

At reduced ME power and/or dirty exhaust boiler, the oil-fired boiler may have to be operated in parallel with the exhaust boiler. Note that the Boiler fan and FO supply pump will start automatically when Burner Management is active. When oil fired boiler stops at increased ME power, the pump and fan have to be stopped manually.

The exhaust boiler consists of a superheater section, a two folded evaporator section, and an economiser section.

Saturated steam from the secondary steam drum (steam generator) is heated in the superheater and is then fed to the turbo-generator.

Water at a temperature close to boiling is pumped from the secondary drum through two evaporator passes. A mixture of steam and water returns to the secondary drum for separation.

The economiser is supplied with water from the feed water tank by the main FW pump. The water is heated by the hot gases in the economiser and the preheated water produced continues into the secondary steam drum. Normally no boiling occurs in the economiser. The exhaust flow passing the heating surfaces is dependent on the total exhaust flow and the exhaust damper position which is controlled by a PID controller.

Transferred heat at each section depends on the local gas temperature and flow. The heat transfer in the evaporator is sharply reduced if the recirculation pump stops; this reduction causes a gradual drop in steam pressure.

The exhaust boiler should be cleaned regularly, by using the air driven sootblowing equipment, if full turbo-generator power capability is to be maintained.

Exhaust Boiler Damper Control

When the exhaust boiler is in operation, the secondary steam pressure is kept constant by a PID controller which sets the position of the boiler’s gas dampers. When the steam load is low, more exhaust gas is by-passed and vice versa.

When both boilers are in operation, there will be an indeterminate load sharing and possible oscillations if the pressure set \points of the master controller and the damper controller are set equally. Realistically, large backlash in the damper positioning gear can easily be simulated by adjustment of the hysteresis element.