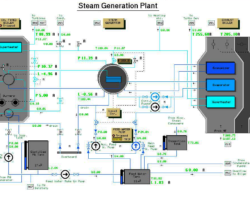

The system is to be operated in two main modes:

a) Cargo pumping

The exhaust boiler and the TG are normally out of operation. The steam pressure of the secondary steam drum is operated at approx. 13 bar, supplying steam to the cargo pump turbines, capacity approx. 50 t/h. The primary steam pressure will vary according to load from 15 to 50 bar.

b) Fuel heating/TG operation

This mode is for miscellaneous steam heating purposes, and if the ME is running, for utilizing waste heat in the exhaust gas. The steam pressure will vary according to load conditions and exhaust energy, between 8 and 12 bar. The minimum pressure of 8 bar is maintained by automatic operation of the oil fired boiler, while the exhaust damper control limits the pressure to 12 bar.

The steam generation plant consists of an exhaust boiler and an oil-fired boiler connected together by a common steam generator.

To simplify the model drawing, the steam generator is presented as a separate unit. Often this is built together with the oil-fired boiler as a secondary drum placed over the primary drum (double pressure boiler).

Steam from the oil-fired boiler’s primary system is condensed to water in the steam generator and flows by gravity back to the primary drum.

The water in the steam generator (secondary steam drum) flows by forced circulation to the evaporator section of the exhaust boiler and a mixture of water and steam returns to the secondary steam drum.

The primary water system is hermetically sealed, and normally there is no consumption of primary water. If, however, the primary steam pressure gets so high that the safety valve opens or a water leakage occurs, the primary drum level will decrease.

Refilling of primary water can be achieved by starting the primary make-up pump and

opening the make-up valve.

There are two feed water pumps for the secondary system. The water from the main FW pump is preheated in the exhaust boiler’s economizer section before entering the

secondary steam drum, while the water from the auxiliary FW pump goes directly to the secondary drum. The auxiliary FW pump should be used only for high steam production (cargo pumping). This auxiliary pump has approximately 5 times the capacity of the main pump.

The water level in the secondary drum is controlled by a PID level controller, driving the two feed water control valves in parallel from a common I/P converter.

Both feed water pumps trip at high-high secondary drum water levels to protect steam consumers from “water strike” caused by water in the outlet steam.

The heat transfer in the exhaust boiler is controlled by exhaust dampers which by-pass some of the exhaust from the main engine. The exhaust damper position is automatically set by a PID controller thus controlling the secondary steam pressure.

The condensate from heating and miscellaneous service application returns to a condensate filter/inspection tank and then flows back to the feed water tank.

The condensate from the condenser is pumped directly to the feed water tank.

When the oil-fired boiler is in operation, there will be a constant water consumption due to the burners atomizing steam flow. Open drain/vent valves, blowing safety valves and steam and condensate leakage all reduce the water content in the feed water tank.

Refill is taken from the distilled water tank. Note that consumption of FW in the distilled FW tank is not modelled.

The feed water tank and the filter/inspection tank are modelled with heat loss to the

surroundings. They will therefore gradually cool down if the inlet flows are stopped.

The temperature of the condensate entering the inspection tank is assumed to have a

constant value (80°C).

If the oil-fired boiler or exhaust boiler are dirty they must be cleaned (“sootblowing”).

Secondary steam is used to sootblow the oil-fired boiler and service air sootblows the

exhaust boiler.

The exhaust boiler sootblowing equipment represents a very heavy load on the service air system when in operation.